This solution takes away most of the practical objections data centers have against most common immersion cooling solutions. By using closed cassettes each device is individually packaged resulting in no open “baths” or “tanks” on the datafloor, so no slippery liquid can be spoiled.

By isolating the devices, they can be managed individually, just like regular servers. So this doesn’t require a change in workflow. Where the regular, common solutions interfere with existing infrastructure in terms of airflow and 19″-racks that are already in place, the iXora solution can be fitted right into existing racks. This way, the millions of racks already out there can still be used.

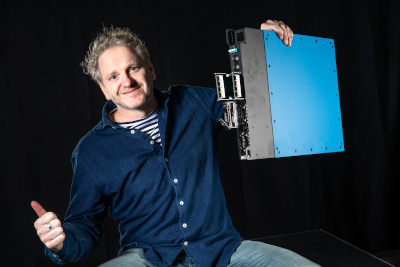

Often people ask why this concept doesn’t exist yet. Our story will probably enlighten that: We think it is because we came to this design while working on a high-performance cooling solution that needed to be rugged and mobile.

For the pro-audio market, the demands are different; off-road use, roadies building stages and moving equipment; quite different from a quiet, stable configuration in a controlled environment such as a datacenter. We NEEDED closed and portable cassettes for our electronics.

Primary, all the fans in server systems consume an average of 20% (yes, twenty percent!) of the used energy for a system. Since liquid cooling doesn’t require fans this is the first step towards savings. Then some simple physics: liquids are somewhere between 1.200 and 1.400 times as effective to transport heat than air; this alone saves a huge amount of energy.

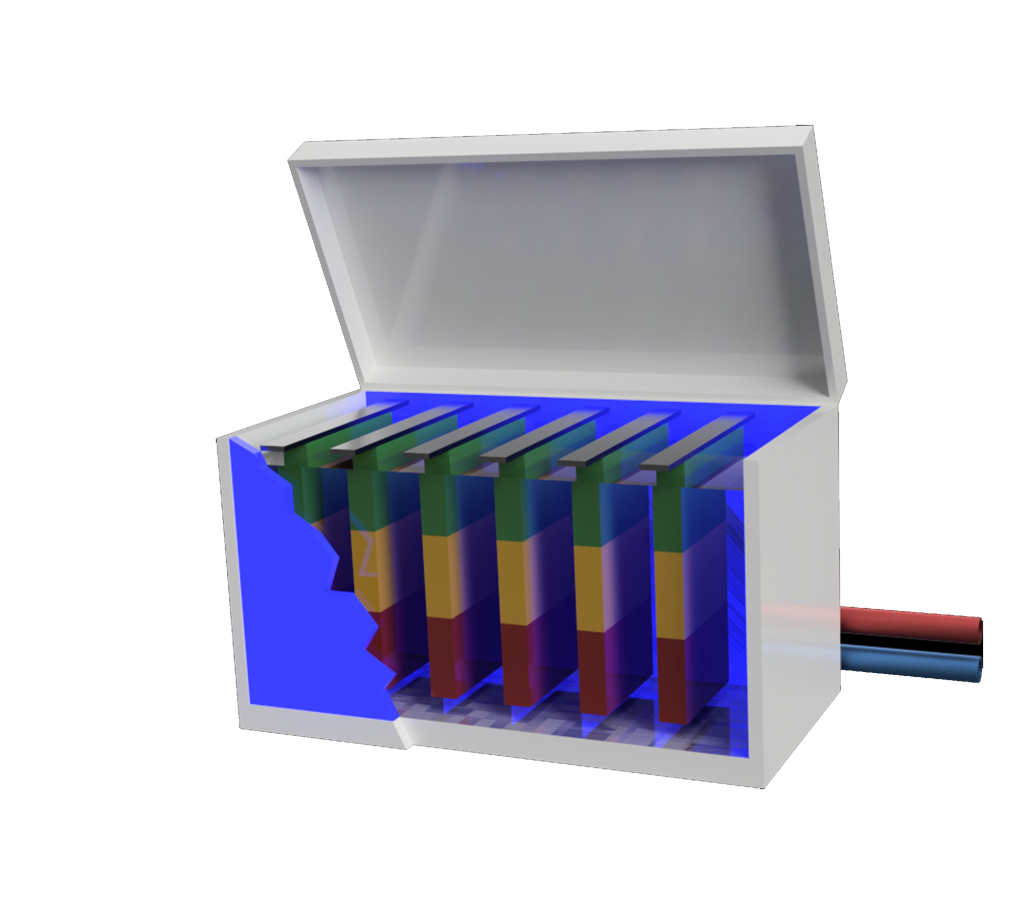

The liquid used in the iXora solution starts flowing upwards when getting hot. This is called ‘natural convection flow’. While heating the liquid, it flows over the vertically mounted electronic boards (motherboard for example). When it reached the top it flows back down through the heatexchanger side where it cools back to it’s cooling temperature. The hot and cold side are separated by an insulation layer to prevent mixing the flow and keep the hot part flowing effectively, just like a chimney. This process doesn’t require any pumps or other moving parts, saving both energy and component wear.

The liquid used for immersion cooling is a so-called “Dielectric” liquid: that means it isn’t conductive for any electricity. So, no shortage or other unwanted behaviour will occur. Nothing to worry about! It even acts as a protective shield against unwanted liquid (i.e. water), dust and microchips’ most feared enemy; static electricity,

No, the liquid used is a 100% engineered and circulair product. It has a lifespan of up to 10 years inside the cassettes with the electronic components and after use it can be completly reused. While the process is not in place just yet, iXora strives to on-site recycling plans in cooperation with the liquid manufacturer. Before that, you can easily drink it and use it as a laxative. Although, officially we don’t recommend that.

Immersion cooling is a way of cooling IT components or other electronics, including servers, routers and storage devices, but also amplifiers, medical equipment and high-power radio transmitters.

By completely sumberging the components in a dielectric, thermally conductive liquid the components can efficiently release their heat into the liquid. The liquid then circulates to transfer the heat towards heat exchangers that can either convert it into air or a usable hot water source. The latter one is the most interesting one in the transition towards energy neutral datacenters. With enough heat transfered into the datacenter watergrid, it becomes a possiblity to heat entire cityblocks.

The liquids used primary must comply to the physical aspect of being absolutly not conductive for electricity. If they would be, they would be causing shortage and damage or at least change the behaviour of electronic components.

Basically they come in two forms; ‘Hydrocarbons’ (for example mineral, synthetic or bio oils) or ‘Fluorocarbons’ (for example fully engineered liquids) and can be divided into two applications. iXora uses a single phase solution, where natural circulation takes heat from the components across a heat exchanger.

The second application is the so called ‘two phase immersion’ where the heat gets extracted using a low temperature evapuration (cooking) process. The arising gas is cooled down on a heat exchanger and flows down to the liquid bath. iXora doesn’t use this latter method.

By the end of the 19th century, among other electric systems, large transformer installations were already cooled using dielectric fluids (oil-like). This is still being used today.

Already in that period engineers and inventors had found out that the thermal conductivity of liquids are much higher than air. By using this technique better thermal management is possible and higher temperatures around electric components can be controlled.

By the end of the 1960’s one of the world largest computer innovators at the time, IBM, was the first to develop a system for modulair packaged components with immersive cooling.

Not earlier than in the 1990’s it was supercomputer manufacturer CRAY that started using immersive technology for their supercomputers. One of those was actually in the Netherlands, located at the SARA scientific institude.

As energy demand from datacenters was a rising issue, the interest in immersive cooling regained by the end of the 2000’s,early 2010’s. Multiple companies, including IBM, Microsoft, Google, Facebook, etc are working on it. The most common form is open-bath immersion cooling, where a bath is filled with liquid and the server components are hung into it vertically. Technically a great solutions, but not very practical.

As datacenters around the world, especially the multi-tenant ones, won’t allow open bath immersion cooling on their datafloors, popularity remains behind. Within the Open Compute Project, a knowledge sharing and combination of stakeholder organisation aimed to reduce datacenter cost, energy hunger and increase efficieny, a lot of work is being done. Needless to say, iXora is joining the Open Compute Project.